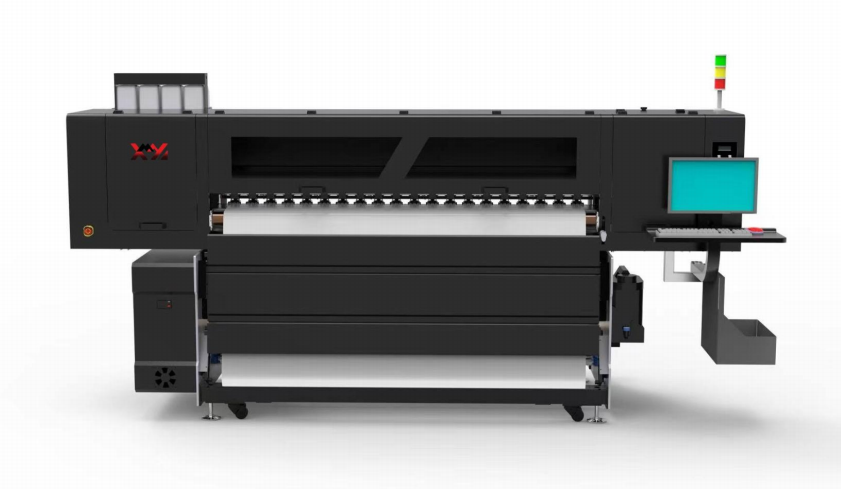

Technical Features and Advantages

- High-density dye-sub inks: Designed for thermal stability and no clogging the printheads during production

- Precise temperature and pressure control: Monitored via built-in thermal sensors to ensure uniform penetration into polyester fibers.

- High resolution and detail: Micro-droplets of 2–4 picolitres with resolutions up to 1440 dpi for photorealistic images and intricate graphics.

- Industrial reliability: Suitable for continuous high-volume production, with self-cleaning nozzles and minimal downtime.